- Best Consultation

Ideal Solution, Perfect Delivery

- 5 Little Road, #05-01 Cemtex Industrial Building

Singapore 536983

Warehouse Management System Singapore

Warehouse management system provides a one stop platform to manage seamless inventory, order, and warehouse operations. It also brings productivity, efficiency, control of your business with minimization of manual processes and work. We cover consulting, developing, onboarding, and training of the warehouse management system. Warehouse Management (WMS) solutions additionally enable companies to maximize their labor and space utilization and equipment investments by coordinating and optimizing resource usage and material flows. A warehouse management system can reduce the likelihood of errors that could occur when a product is shipped. The system can also help a company fulfill orders more rapidly and instantaneously trace ordered products within the warehouse. Our WMS is the leading cloud-based warehouse management system in Singapore. With innovative product features, mobile solutions, and an easy-to-use interface.

Enhanced Stock and Inventory Tracking

Accurate stock balance and inventory tracking with detailed listing of purchase and packing orders

Ensure Data Accuracy

Item label and order slip printing and scanning option will ensure the data accuracy

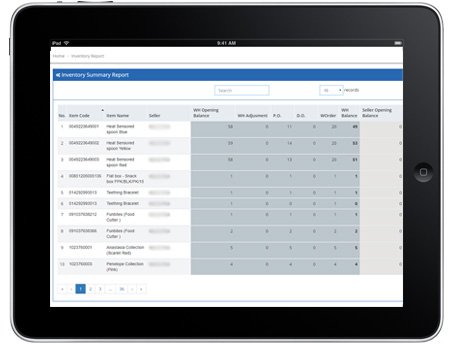

Inventory & Sales Report

Inventory & Sales report directly depends on the PO and SO. Both summary and detail view is available.

Simplify Order Processing

Advanced modules like quotation, packing list and process of packing list makes the solution very systematic and simple

Sellers Portal Access

Sellers can have their own portal to view and add packing list to ensure no communication gap and they can access all reports

Integration with Driver Management System

Warehouse management system can be integrated with our driver management system which can allow to allocate and track drivers movement

Data Export & Import

All data listing can be exported to csv and many listing like inventory, packing list, order list can be imported from excel to the system

API for integration

We provide API for external software integration to bring in the packing list to our system

Features of warehouse management system

Inventory Tracking

Warehouse management system includes inventory tracking system. Inventory balance can be handled using purchase order, delivery order, inventory adjustment and outbound orders. Each seller can maintain his own inventory. Seller can have comprehensive reports for item costing detail, items selling report, purchase history and item balance breakup etc which can be exported to csv. System can send email notification for low balance of items and auto generate the purchase order. This system has all the required feature to maintain inventory with ease.

Warehouse Quotation Management

Seller database can be created to provide quotations and offers for storage and delivery. Quotations sometimes may require many revisions until the seller accept the quotation. Many charges might include in quotation like inbound charges, outbound charges, packing materials, manpower, peak charges etc.. All these charges can be handled with different criteria for different seller. This makes the system very flexible and unique.

Picking and Packing Goods

Warehouse management system will give a detailed order process where the order will go through certain stage to ensure all the items ordered and packed matches and the right items are picked and packed. Once the order is packed, all the details like packing material used, weight and dimension of the packing and other details like additional manpower can be added to the order which will be used for the order charge calculation.